EN

The exact term for a spray painting booth should be "spray baking painting booth," which provides a relatively enclosed and clean space that can maintain a certain temperature for the sprayed items. Spray booth types can be simply divided into dry-type and wet-type based on the method of paint mist treatment. Wet-type spray painting booths can further be categorized into water curtain spray painting booths, pump-free water curtain spray painting booths, and water swirling spray painting booths. Therefore, the four common paint booth types are dry-type spray painting booths, water curtain spray painting booths, pump-free water curtain spray painting booths, and water swirling spray painting booths.

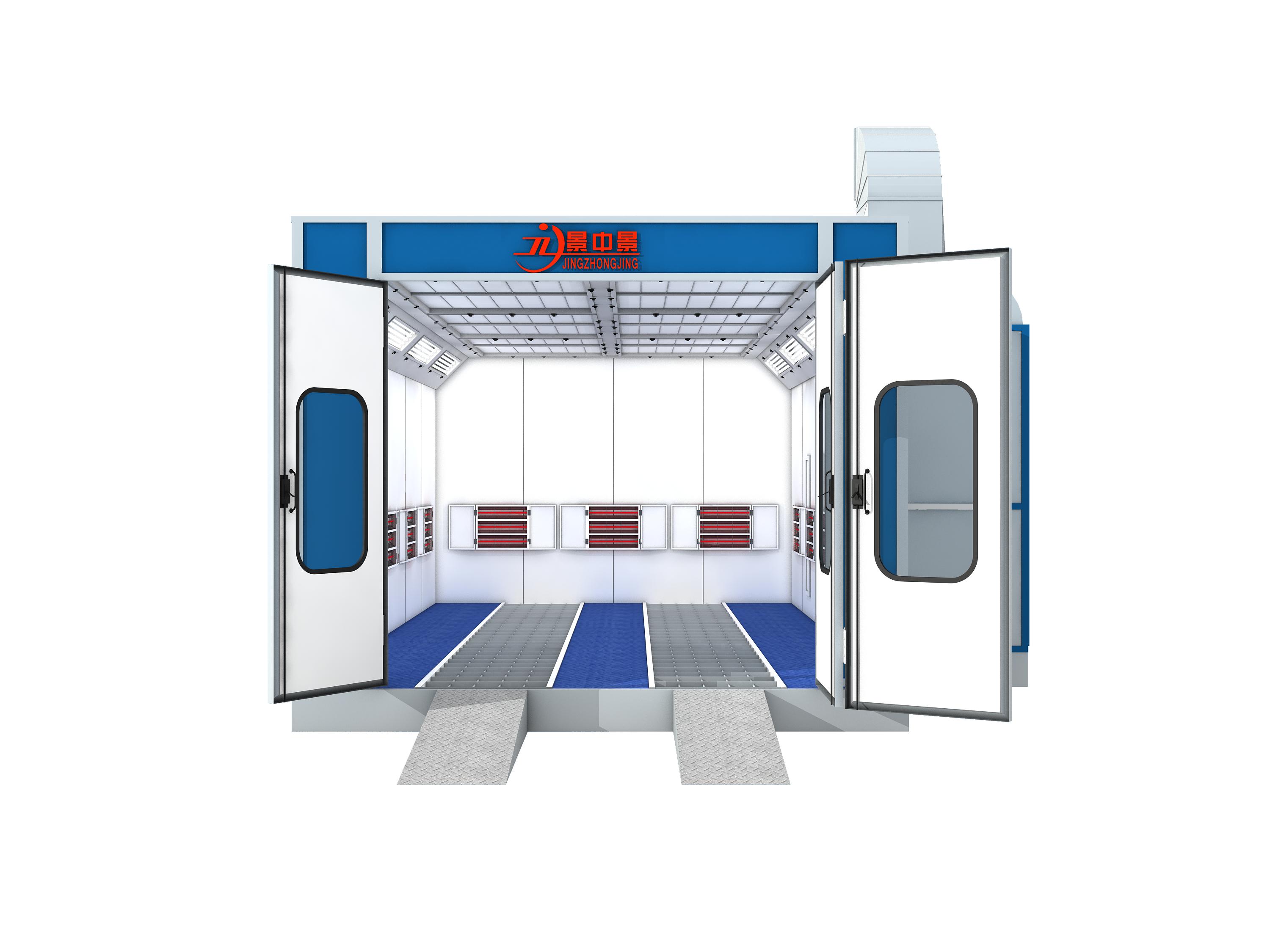

The dry-type spray painting booth is currently recognized as one of the most complete technical spray booth types. It improves on the old spray painting rooms, which had significant pollution in the working area, poor paint mist treatment ability, low safety, unstable performance, and inability to meet environmental protection requirements. This paint booth type features advanced design, reasonable structure, beautiful appearance, high paint mist treatment efficiency, stable performance, safety and reliability, strong rigidity, and shadow-free lighting. The main components of the dry-type spray painting booth include the room system, passive air intake filtration system, paint mist filtration system, organic waste gas treatment system, exhaust ventilation system, lighting system, and control system.

The advantages of dry-type spray booth types include simple structure, uniform ventilation and air pressure, low paint consumption, and high coating efficiency. Since water is not used, wastewater treatment is not necessary, leading to low operating costs. The spray painting room is free from water and oil pollution.

The water curtain spray painting booth is a wet processing device among the various paint booth types. The front of the equipment features a water curtain panel, with an overflow trough at the top and multi-stage water curtain filters behind it. During spraying, the paint mist entering the spray painting equipment for sale first encounters the water curtain and is washed into the water tank. The remaining paint mist is intercepted in the water while passing through the multi-stage water curtain filters. The water in the tank is lifted by a pump to the overflow trough atop the water curtain and multi-stage water curtain filters, forming a water curtain as it overflows onto the water curtain panel. The water curtain panel in the room is made of stainless steel, featuring an advanced and reasonable design to ensure airflow speed within the room, improve painting rate and paint residue capture rate, and create a uniform, continuous, reliable water curtain without intermittent splashes. The vortex device, combined with the gas-water separation baffle, can fully wash and separate residual paint and gas-water, achieving environmental purification and making it convenient and effective to handle paint residue cleaning and maintenance on the panel. The water curtain spray booth consists of the room body, water tank, stainless steel water curtain panel, water circulation system, and exhaust filtration system, effectively preventing the discharge of waste paint and environmental pollution while completing the coating of the workpiece.

The working principle of the water curtain spray painting booth: the workpiece is delivered into the spray painting room via a hanging conveyor or placed on a rotating work table. The operator uses a handheld electrostatic spray painting gun or a fixed rotary cup spray painting gun to coat the workpiece. Using an electrostatic spray gun, the paint mist collection effect is excellent. The overspray paint mist is attracted by the airflow to the water curtain for purification, and after being purified by the gas-water separation device, the clean air is discharged outside the room. The paint mist captured by the water curtain flows into the water tank, is filtered by the water pump, with paint residue floating on the water surface. By adding coagulants to the water tank, the paint residue clumps together for easy removal and centralized processing, maintaining water quality cleanliness and achieving paint mist purification.

Application range of water curtain spray painting booths: suitable for spraying workpieces in industries such as machinery, automotive parts, metal products, decorations, home appliances, and furniture. Suitable for single-side spraying, and multiple units can be combined for double-sided spraying.

The pump-free water curtain spray painting booth is another of the paint booth types that uses air induction to form a circulating water curtain. Air containing paint mist collides with the water curtain, passes through the curtain into the gas-water channel, where it intensively mixes with the water. Upon entering the gas collection tank, the flow rate suddenly decreases, separating the gas and water. The separated air is discharged into the atmosphere via the exhaust fan, and the water gathers in the gas collection tank before flowing into the overflow trough, forming a water curtain on the splash plate and flowing back to the water tank. A special coagulant is added to the circulating water to alter the adhesion state of the paint mist, causing it to clump for easy cleaning. Principle: using the high-speed exhaust to induce water, the exhaust system and the water lifting system are integrated into a pump-free water circulation system, eliminating the need for a water pump circulation supply system. This simplifies the structure, reduces the footprint, avoids the clogging issues common in various water pump supply systems, makes maintenance easy, and ensures reliable performance and trouble-free usage. The multi-stage purification process involving the water curtain, water splash plate, gas-water channel, and water mist mixing enhances purification efficiency.

The working principle of the pump-free water curtain spray painting booth: during operation, the workpiece is placed on a rotatable work platform in the front room, with the painter spraying facing the workpiece. The airflow formed by the suction of the fan flows from outside to inside, directing the spray mist through the spray painting room and outside the workshop, ensuring that the workshop and painter's environment are not polluted by the paint mist. The paint mist is treated by water before being exhausted. The front-through room is suitable for large-volume spray painting of small and medium-sized workpieces. The workpieces are introduced into the spray painting room from one side using a hanging chain and exit from the other side, with the painter completing the spraying as the workpiece passes through the front room.

Application range of pump-free water curtain spray painting booths: suitable for spraying and paint mist filtration in industries such as machinery, electrical instruments, light industry, aircraft, locomotives, etc.

The water swirling spray painting booth uses upward air supply and downward exhaust, with paint mist capture devices located at the bottom of the spray painting room, suitable for medium to large workpieces. Using water as the medium, it employs an upward air supply and downward exhaust method, allowing paint mist and water to fully mix in the lower part of the spray painting room. The booth can be of varying sizes, suitable for high-end spraying of medium to large workpieces.

The working principle of the water swirling spray painting booth: fresh air enters the top of the water swirling spray painting room through the air conditioning unit, passes through the plenum and filter layer, and is uniformly delivered inside the room at a terminal airspeed of 0.45m/s, creating a uniform airflow layer from top to bottom. Once the workpiece is placed in the airflow layer, splashed paint mist is pressed into the water swirling spray booth's water swirling device, where water is atomized by the high-speed airflow, thoroughly mixing with the paint mist, thus attracting and removing the paint mist into the water. The moisture-laden air is then separated at the gas-water separaor, and the clean air is exhausted into the atmosphere by the exhaust system, achieving a paint mist purification rate of ≥98%. The water containing the paint mist flows into the circulation water tank, coagulated and purified (with special coagulants regularly added to the water), and is pumped back to the spray painting room for reuse, with floating paint residue periodically skimmed out for deep burial or incineration treatment.

Application range of water swirling spray painting booths: suitable for coating applications on household appliances, bicycles, household and commercial steel furniture, automotive and motorcycle parts, instrumentation housings, electrical cabinets, agricultural machinery, sports equipment, and others.