EN

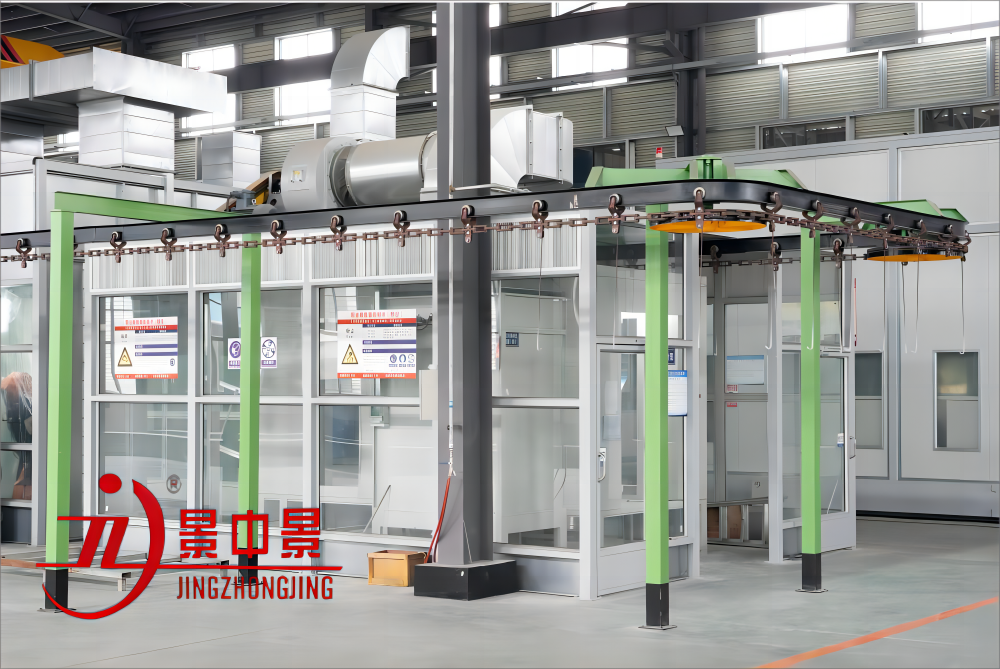

A coating production line is an automated production line used for spray coating products. The main components of a coating production line include a pre-treatment system, drying equipment, spraying equipment like the container spray booth, curing system, etc. The entire process uses a conveyor system to connect products with various processes seamlessly. The intelligence and automation of coating production lines are the development trends in modern manufacturing. Manufacturers of coating production lines continuously develop advanced technologies independently to achieve efficient, precise, and stable production. The application of coating production lines is also very extensive, such as in the automotive, hardware, cookware, woodworking, and industrial equipment industries. By improving the appearance and quality of products, they can meet the production needs of different products, reducing coating costs while improving production quality, ultimately achieving cost reduction and efficiency improvement.

Before spraying, the workpiece needs to go through pre-treatment cleaning equipment to remove dust, rust, grease, and other impurities from its surface, making the adhesion between the coating and the substrate stronger. A protective film is formed on the surface to improve the corrosion resistance of the coating and extend its service life. The pre-treatment system can reduce the defect rate in subsequent coating processes, thereby lowering production costs.

After pre-treatment, the product will pass through drying equipment to quickly evaporate the moisture or solvent on the workpiece surface, improving production efficiency and accelerating the production rhythm. The drying equipment can uniformly heat the workpiece surface to avoid issues like bubbles and cracking.

This is followed by the formal spraying system. Common spraying systems include manual spraying, automatic spraying, and electrostatic spraying. Small or regularly shaped workpieces usually use automatic spraying equipment like auto spray booth for sale. Robot automatic spraying offers high precision, fast efficiency, and reduces labor costs while also minimizing paint waste and environmental pollution. Large workpieces and irregularly shaped parts can also use a combination of robot automatic spraying and manual touch-up to ensure product quality. Pure manual spraying has lower initial investment costs, but higher labor costs during use, and its spraying efficiency and quality lack uniform standards, making it more suitable for extra-large irregular workpieces.

After spraying treatment, the workpiece will go through curing equipment for drying processes. Typically common are high-temperature curing and UV curing. High-temperature curing usually suits workpieces that require abrasion and chemical resistance (such as metal materials), allowing paint to quickly cure into a film, enhancing the hardness and durability of the coating. UV curing refers to curing the paint through ultraviolet light without heating, suitable for heat-sensitive workpieces (such as wooden furniture and musical instruments), with fast curing speed, improved production efficiency, and superior surface gloss and quality.

Finally, it's worth mentioning that various equipment in the coating production line will use conveyor equipment to connect. Common conveyor equipment includes hanging conveyors, flat conveyors, skid conveyors, and support conveyors. Each type of conveyor equipment has its unique advantages and features. Businesses should comprehensively consider their production needs, workpiece characteristics, plant area, and other factors when choosing. They can also combine multiple conveying methods to achieve optimal results.